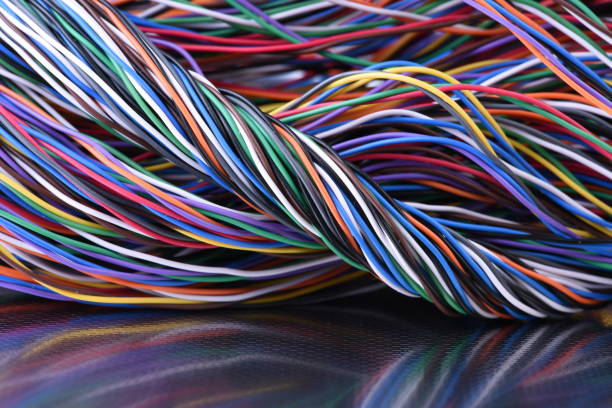

Wires are undoubtedly one of the critical components in our households and outside. They ensure everything from electrical connectivity to powering our virtual devices. Industrially, their importance cannot be undermined, primarily because they are present everywhere. Given their enormous presence, wires come in various shapes and sizes. For a larger scale of electrical transferability, larger wires are used; for a typical household, the more conventional types are preferred.

Since wires need to be fitted according to the needs and requirements, it becomes exceedingly important to cut them properly. There are numerous types of cables; hence their cutting technology and procedures also vary.

Why cutting wires properly is necessary?

Wires and cables come in various shapes and sizes depending on their necessity. Some wires are produced in specific lengths, but they usually need to be trimmed when installed. Different types of wires are conducive to particular residential and industrial settings.

Some of the most common types are:

- Service drop cable

- Main feeder wires

- Single conductor wire

- Coaxial cables

- Twisted pair cables

- Fiber-optic cable

Ideally, with different wires and cables, the cutting techniques would also vary. This is where a professional wire company can help you with shaped wire cutting services. Such companies have the required tools and expertise that ensure prompt project fulfillment and superior service.

Wire Cutting Methods

Full cutting and stripping

One of the most common wire and cable-cutting methods involves completely removing the exposed insulation at a preferred length and size. This process is entirely physical, and the purpose of this technique is to detach the insulation and the jacketing so that the conductor situated in the center is wholly exposed.

Additionally, this is a preferred method for terminations, where the wire needs to be crimped or soldered.

Partial cutting and stripping

Unlike the first method, the wires and cables are cut partially. Here the wires are cut from a particular end, preferably at the end, so that the desired length is achieved. Additionally, the insulation is left on to protect the inner conductor as a part of the wire has been stripped. The components of the wire that are located inside are also covered.

This form of cutting highly speeds up the wire-cutting process because when electricians work on such a project, they are required to cut and strip.

Blunt Cutting

Relatively more straightforward than both the methods mentioned above, blunt cutting simply involves the division of the wires and cables into several different components. This is one of the simplest and fastest wire-cutting techniques used by professionals. The residual wiring is either saved for future projects or discarded altogether.

Additionally, the end of the wires is usually left untouched and attached so a desired length for the wire can be identified. However, more energy needs to be invested to achieve the desired outcome.

Manual Cutting

Since we have discussed the three most prominent methods of cutting wires, it’s also essential to understand how we can achieve them accurately and efficiently. Manual cutting is the most common form of wire-cutting technique, and it’s also the oldest. It’s used by the most basic of electricians to the highly mechanized ones.

Some of the steps involved in this method are:

- Identifying the wire gauge

- Penetration of the external sheathing

- Protection of the inner conducting metal

- Matching the wire with an accurate hole

- Accurate piercing of the insulation

- Removal of insulation

However, one of the crucial drawbacks of this method is that it’s way too time-consuming, as everything takes place manually.

Automated Cutting

Unlike manual wire cutting and stripping, automated cutting is usually done by highly effective machinery. Automated cutting is applied individually for cutting and stripping wires with different gauge sizes. This procedure primarily cuts wires in large quantities to conserve time and achieve precision.

Additionally, the mechanical scale of automated cutting enables the cutting and stripping of wires in a matter of hours.

Wire Cutting Tools

Scissors

Scissors are an ideal alternative for wire cutters and perfect for small-scale wire cutting. Household scissors can easily cut the outer coating of wires and, after a bit of resistance, can get through the wire.

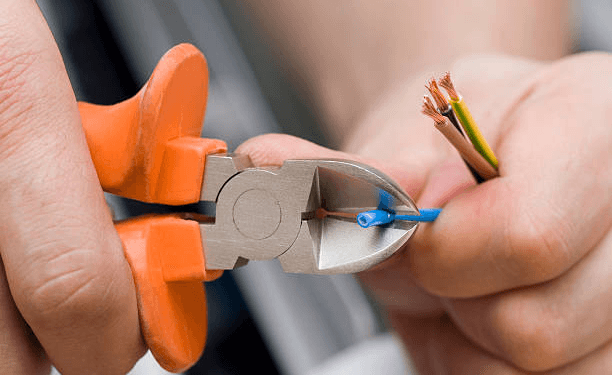

Pliers

Similar to wire cutters, pliers are great for cutting wires with rubber protection. They are safe and easy to hold, and their precision levels are also high compared to scissors.

Hacksaw

Hacksaws generally don’t provide a cleaner cut than scissors and pliers, but they are highly effective for larger wires. However, the user needs to be extremely careful when operating the tool since it is enormous.

Grinder

Even though an unconventional tool, grinders are used for wires too small to cut with any other tool. The rotating blades can cut the inner metals quickly and accurately. While using this tool, ensure that you’re wearing goggles.

Conclusion

Wires come in various shapes and sizes, so their cutting process also varies. With adequate methods, this time-consuming activity can be accomplished effectively.